Your Trusted Partner in Contract Manufacturing

From precision moulding to large-scale assembly, Emox delivers tailored manufacturing solutions across multiple industries. With in-house R&D and end-to-end capabilities, we bring quality, scale, and flexibility to every partnership.

Industries we serve

-

Helmets

End-to-end manufacturing of helmet components and accessories, including certified testing and assembly.

-

Toys & Leisure

Design, moulding, and assembly of plastic toys and ride-ons, including kick scooters.

-

Electronics

Assembly of electronic consumer products like mosquito repellent devices with soldering, crimping, and quality inspection.

-

FMCG

Packaging and filling for personal care, homecare, and food products—trusted by top consumer brands.

Our Capabilities

Emox Group offers a comprehensive suite of manufacturing services, built around decades of moulding expertise and end-to-end production solutions:

-

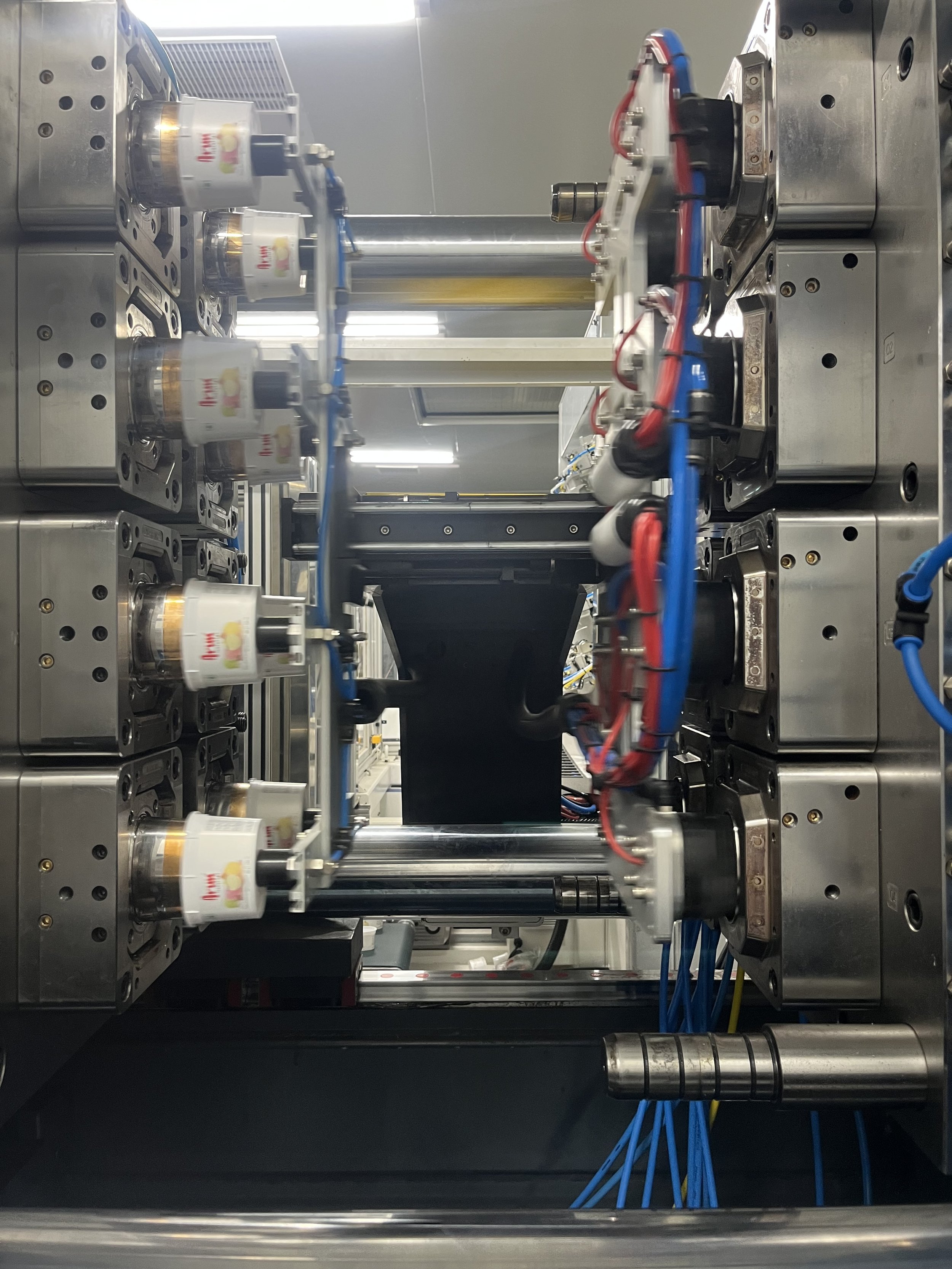

Precision plastic moulding—low to high-cavitation (up to 8 cavities)—delivering complex components, built-in IML options, and assembly-ready parts at scale.

-

Hollow-product solutions—from extrusion blow moulding of containers to high-speed PET stretch-blow for beverage, cosmetic, and pharma packaging—ensuring lightweight strength and clarity.

-

Seamless in-mould labelling for integrated branding and decoration, plus semi-automatic paint lines, decal application, and hard-coating for lasting finish.

-

Semi-automatic paint booths, baking ovens and hard-coat lines for durable, high-quality finishes on helmets and housings.

-

Wave soldering, crimping, wire cutting and full QC for consumer-electronic devices, from mosquito repellents to bespoke electronics.

-

Stitching, laser cutting, embossing and clicker operations—supported by 30+ stitching machines for high-throughput textile assembly.

-

High-volume assembly & filling lines, auto-capping, screen-printing with camera inspection, and electronic assembly (wave soldering, crimping, wire cutting) for FMCG, automotive accessories, electronics, and more.

-

Full tooling design, electronic design & prototyping, and QC lab testing (BIS/ECE for helmets and toys) to accelerate product development and validate performance before full-scale production.

Our company vision

At Emox, we envision a future where manufacturing is not just a service but a strategic advantage—delivered through fully integrated, end-to-end solutions that combine precision moulding, assembly, finishing, filling, and packaging under one roof.

We are committed to uncompromising quality and reliability, continuously refining our processes and adopting cutting-edge technologies to exceed the highest industry standards. By placing exceptional customer service at the heart of everything we do, we build transparent, responsive partnerships that drive mutual success.

Through sustainable practices and a culture of empowered, innovative teams, we turn every manufacturing challenge into an opportunity for growth—both for our customers and for Emox. Learn more

KEY FACTS

5 Plants across India

•

20+ years of customer relationship

•

1500+ skilled manpower

•

30 million total assemblies per year

•

200 million bottles filled per annum

•

5 Plants across India • 20+ years of customer relationship • 1500+ skilled manpower • 30 million total assemblies per year • 200 million bottles filled per annum •

Trusted by Industry Leaders

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!